Dragstrip Track Prep & More TVC Services

From Consulting to Hands-On Maintenance, We've Got You Covered for Track PrepWhat Does TVC Do?

Just as race car performance has advanced, so have the technologies used in prepping race tracks. Twenty years ago, a Pro Mod made 2,000 horsepower. Today these machines are exceeding 5,000 horsepower. Do you think those twenty-year-old track prep techniques are adequate for today’s needs? Let Total Venue Concepts educate your employees on modern surface preparation and how to utilize the best equipment to employ these proven techniques.

Design (Minimize the Design Mistakes)

Concrete (Make the TRACK Stronger)

Grind (Make the TRACK Smoother)

Texture (Give the TRACK Teeth)

Cleaning (Scrubbers)

Rubbing (Drags)

Spray (Sprayers)

Rotate (Rotators)

Run Cars (Staffing your Event)

Scrape (Scrapers – Machines and Hand-Held Tools)

Surface Repairs (Fix It)

Rentals (Don’t Buy… Rent it!)

TVC Track Design and Project Consulting

DESIGN: Are you considering a track renovation or building a new facility? Let Total Venue Concept assist you. Years of experience, including trial and error, will save you from pitfalls. Even quality contractors DO NOT understand what is needed for a quality competition surface!

- Complete flatness and texture specifications

- Hundreds of hours of written specification and instructions

- Concrete Mix Designs (many mistakes can be saved here)

- Asphalt Mix Designs that work (Proper mix for climate and use)

- Where to use the most cost-effective material

- Sub Base, Subgrade, and Surface design and specifications

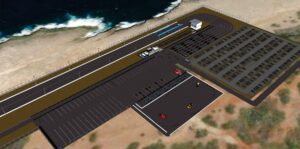

- Overall, park design for proper competition flow

- TVC does NOT guess; we used proven designs

- Spotting costly mistakes BEFORE they are permanent

TVC Track Reclamation Services

PATCH WORK: Concrete derogates over time; it’s that simple. Add the routine of scraping and the traction compounds we use on the surface, which speeds the process up considerably. Degradation often happens at control joints. TVC can replace damaged areas of your race surface using specialized concrete mixes and techniques to replace the affected areas. After the replacement area is ground flat, the entire area is checked for flatness and appropriate texture. These repaired areas have proven to have a seven-year-plus lifecycle. Compared to replacing the entire surface, the cost of repairs depends entirely on how much needs to be replaced. There is a likely chance that we can save you a considerable amount of money while significantly improving your competition surface.

PROFILING: TVC acquired a dual-axis inclinometer longitudinal profiler. What does this mean to you??? NO MORE GUESSING! TVC can measure your track and tell you exactly where the bumps and dips are. If we determine that a profile grind is necessary, we have information to grind precisely how much and where. Profile measurements are a true game-changer. Additionally, the profile measuring tool allows us to bump grind your surface only where you need it; this saves time and money and prolongs the lifespan of your racing surface. Also, the walking profiler is used to certify an Inertial Profilers system, as you may see on a pickup truck. In plain English, it is more accurate.

TRACK GRINDING: There are two methods of track grinding…

– Profile Grinding is a large machine with approximately a 20′ wheelbase. The front wheel follows the track’s profile (Moving with the bumps and dips), but the rear cutting head stays relatively flat as it is mounted near the rear wheel’s fulcrum point.

– Profile Cutting provides a flat cut of the surface even. The surface is then checked with the longitudinal profiler to assure flatness. The profile grind is cut with two heads a very corse head to move through large amount of material quickly, then a second head is installed and the track is cut once again removing much finer details. Then TVC removes the much too rough corduroy texture with large remote control diamond rotary grinders with large vacuum systems. This removes any mismatches and leaves a diamond cut texture that holds rubber. the vacuums greatly lesson the clean up process.

HYDRAULIC DIP RASING: It used to be the only way to remove a dip was to grind it, NOW we can raise a dip using hydriodic cement. This process can be completed over the entire competition surface, then the bumps are profile ground, and your race track is flat with MUCH LESS grinding into the aggregates. Or we can raise an isolated dip and grind to flat to surrounding area using our remote control large frame rotary grinders.

TEXTURE/BUMP GRINDING: TVC can identify bumps and dips if there are just a few problem areas we can remove those with out using the large profile grinder. We have large format concrete planers and grinders that can quickly remove problem areas. Or possibly your track just does not hold rubber like it use to. TVC can remove a small amount of the top surface leaving a deep diamond texture that has proven to hold rubber.

Design

Concrete

Grinding

Texture

Cleaning

Dragging

Spraying

Rotate

Run Cars

Scrape

Surface Repairs

rentals

DESIGN

Are you considering a track renovation or building a new facility? Let Total Venue Concepts assist you. Years of experience, including trial and error, will save you from pitfalls.

Even quality contractors DO NOT understand what is needed for a quality competition surface.

- Complete flatness and texture specifications.

- Hundreds of hours of written specification and Instructions.

- Concrete Mix Designs (many mistakes can be saved here)

- Asphalt Mix Designs that work (Proper mix for climate and use)

- Where to use the most cost-effective material

- Sub Base, Subgrade, and Surface design and specifications

- Overall, park design for proper competition flow

- TVC does NOT guess; we used proven Designs

- Spotting costly mistakes BEFORE they are permanent

(References available upon request)

CONCRETE

When you’re ready to put down a new racing surface, Total Venue Concepts can provide your ready mix and placement team with a series of specifications that can help you create a performance clause for any surface quality. A performance clause becomes part of your warranty from the placement and ready-mix team; this can save you hundreds of thousands of dollars down the road.

Additionally, we know what mixes work in what areas. We also have developed a flatness spec; that reduces or eliminates grinding.

“How should you cure your concrete” and “what type of finish needs to be placed onto the surface?” These are questions Total Venue Concepts can answer.

GRINDING

TEXTURE

CLEANING

Cleaning a racetrack is the most important procedure you can do for your race track. There are many techniques for cleaning your racetrack, and a significant number of machines made to clean a flat surface. Total Venue Concepts customizes existing floor scrubbers to work correctly in a race track environment.

Our scrubbers have broom bristles that are the right texture and stiffness. We have chemical delivery systems that apply the correct cleaning compounds to efficiently and quickly clean up a mess, or maintain your track every week. Weekly maintenance cleaning of your race track will provide a surface that's able to provide a better traction coefficient and will require less traction compound.

Regular cleaning maintenance of a racetrack also decreases the need for scraping, reducing staff hours and payroll. Total Venue Concepts also rents scrubbers and staff for special events and or track clean up after grinding and texturing. Call Total Venue Concepts for a complete explanation of the various machines available, or to request a quote to have machines and/or staff brought to your facility for a special event.

STATIC DRAGGING

Dragging a racetrack started approximately 30 years ago. Initially, large tractor tires were merely tied to the back of a pickup truck via rope or chain, then drug up and down the race track to transfer rubber to the surface. Over time, landscaping style box blades were converted with tire belts placed around the cutting blade which not only cleaned the track but transferred rubber onto the surface. But race surfaces are rarely truly flat the sizeable cutting edge would not push the tires into the low spots of the track.

Total Venue Concepts has taken the process far beyond that. We offer Hook Master static drags that have a complete suspension system that follows the contour of the racing surface which applies an even layer of rubber. Additionally, this process helps cleans the top of the surface which is why the TVC Hook Master suspended static drag is utilized by many of the top tracks in the country. Hook Master drags are available in multiple widths to pair to the size of your tractor.

Total Venue Concepts Hook Master static drags move rubber from high spots on your track, placing it in the low spots to help create a smooth, even surface while at the same time helping clean the surface and adhere a thin layer of racing rubber to your competition surface.

SPRAYING

Traction compound is an essential component of a quality surface. Spraying traction compound on a racing surface is not as simple as it sounds. No matter what brand of the compound you prefer product delivery and how the compound pays on the surface are critical.

Just the nozzles alone have multiple factors that influence the finished product. Nozzle height, spray pattern and delivery rate selection are all critical to gaining the most consistent surface.

Traction compounds are very expensive. A Total Venue Concepts traction compound sprayer will not only deliver exceptional traction compound coverage and penetration. A TVC sprayer can SAVE you money; our sprayer wholly atomizes the compound mixtures, allowing you to use less compound to receive the same result.

A feature of the Hookmaster Competition Sprayer is variable spray widths. The operator can control how wide of a spray pattern they are putting down. You can choose from an 8 foot, 12 foot or 16’ spray pattern, only apply traction compound where you need it.

For example, on the morning spray, you may spray the entire lane stripe to stripe to help give a competitor the ability to save a car if they are out of shape. During touch-ups, you may choose to spray only at 8’ wide from the line to 60 feet. At 60’ open the 12’ setting and only spray 12 foot to 300’ and spray 16’ further down track. Remember the narrower the spray pattern, the more product you will be putting down per nozzle, due to the fact, your nozzle area is less, but product pressure is the same. So you can move your tow vehicle much faster and put the same amount of product down. As you open more nozzles down the track, you slow the tow vehicle down to apply the same amount of product. The final result is over two years; you may be able to to save enough in traction compound to pay for the sprayer.

Go Faster with a TVC Sprayer, when in an unlimited budget situation such as record radial racing, a TVC sprayer will help the ridiculous amounts of glue layer to thoroughly dry quicker, creating a firmer and thus faster surface.

ROTATE (BUILD ROTATING STUFF)

Rotating drags have been around approximately a decade. The concept is to simply rotate a rim with a mounted, inflated race tire rotating backwards, behind a tractor, which transfers rubber to the racing surface.

Rotating your surface not only smooths existing rubber/compound base it can revitalize exiting traction compound saving you money over time and providing a consistent surface for your competitors.

Total Venue Concepts took the concept of rotating drags to the next level. Our rotating drags provide a fresh approach to the rotating concept. We improved the performance and ease of maintenance of the TVC Hook Master 4 tire Rotating Drag. We produce a rotator with numerous options and provide exceptional education and customer support.

Total Venue Concepts highly recommends that a quality base rubber surface is placed on your track either after refinishing a surface; at the start of a new season or before a special event. Contact us about renting or purchasing rotators, static drag with power units (Tractor), and operators.

RUN CARS (STAFF YOUR EVENT)

Total Venue Concepts can supply your event an individual employee in almost any position. Timing, Tech, Operations, Starters Parking Managers, Ticketing Managers etc. Do you want to put an event on but need staff, we can supply a turnkey employee package.

SCRAPE (BUILD SCRAPING STUFF)

TVC can supply you with scrapping supplies, torches Blades, Handles, 100 lbs propane bottles and caddies and even Skid Steer scrapers.

Torches we only use Machester “turbo” Style torches 750,000 BTU. These torches provide a very directional heat pattern. Keep your rubber hot and yet will not burn your rubber roll or warp your blade if used properly. These torches also feature an excess supply check valve to lessen the chance of an accident.

Blades we can supply a scraping blade that if properly used will last you an entire season.

Handles we have several scrapers handles to chose from, robust round handle to our exclusive to completely adjustable “Crutch” Scraper handle.

We offer full flow valve propane bottles and rugged, dependable bottle caddies that provide very strong reliable wheels. The caddy makes it very easy to change the bottle and keeps your people safe and secure.

The TVC Skid Steer Scraper is state of the art. It offers an unheard of 36” cut path. We use three individual blades to allow each blade to follow irregularities in the track surface and provide you with a smooth, consistent scrape. Click here to see our skid steer scraper.

SURFACE REPAIRS

Concrete degradation is common on race racks around the country. Northern tracks have the worst issues due to the freeze and thaw cycles.

Normally, the degradation begins at control joints. A combination of water freeze/thaw cycle, tire dragging, scraping rubber, high power traction compounds all work to destroy your concrete.

Think about it: when you are proud of that track and you can barely walk on it, just think the force a soft race slick puts on the chemically enhanced surface, trying to constantly rip the concrete aggregates out. We haven’t even talked down force, a Top Fuel car puts out and estimated 8,000 lbs. of down force, Pro Mods are in the 3,000 lbs. area. These factors all take their toll on the concrete’s life.

RENTALS (DON'T WANNA BUY IT? WE RENT IT!)

We rent Rotators, Static Drags, Tractors, and Scrapers with operators.

Racetrack Concrete Surface Repairs

Concrete degradation is common on race racks around the country. Northern tracks have the worst issues due to the freeze and thaw cycles.

Concrete degradation is common on race racks around the country. Northern tracks have the worst issues due to the freeze and thaw cycles.

Normally, the degradation begins at control joints. A combination of water freeze/thaw cycle, tire dragging, scraping rubber, high power traction compounds all work to destroy your concrete.

Think about it: when you are proud of that track and you can barely walk on it, just think the force a soft race slick puts on the chemically enhanced surface, trying to constantly rip the concrete aggregates out. We haven’t even talked down force, a Top Fuel car puts out and estimated 8,000 lbs. of down force, Pro Mods are in the 3,000 lbs. area. These factors all take their toll on the concrete’s life.

Before You Remove and Replace Your Race Track,

Possibly Get an Additional 5-10 Years Out of Your Track’s Surface!

Before you proceed with a costly resurface, call TVC first. We may be able to save you tens of thousands of dollars AND extend the life of your existing race surface by years.

Before you proceed with a costly resurface, call TVC first. We may be able to save you tens of thousands of dollars AND extend the life of your existing race surface by years.

Typically, only 2-6% of the total racing surface shows signs of wear and tear. Therefore, it is NOT necessary to repair the entire racing surface. Let TFC show you how to effectively repair only the areas of deterioration.

Don’t waste money! Five or even ten years of extra life could be worth thousands in capital investment. Keep your revenue and/or credit line to use elsewhere.

The Total Venue Concept concrete repair product provides a super-flat spec which will hold rubber year after year. This technique can be used anywhere on the race surface. This system can be used on any concrete surface on your race track. The TVC system has performed well at multiple NHRA National Event venues. Even National records have been set on these repaired surfaces. And the repair product has held up through freeze and thaw cycles without any signs of deterioration in the repaired area.

Total Venue Concept Concrete Repair System Performs!

TVC uses:

TVC uses:

- A proprietary removing and replacing of concrete technique to only damaged areas of the race surface.

- A proprietary Concrete Mix is used, which is stronger and flexible than the original concrete surface.

- The repaired area is ground super flat

- A quality texture pattern is ground into the new concrete and surrounding area that attracts and holds rubber

- Control cuts are placed into the repaired (restored) area to allow your racetrack to move with temperature changes as originally designed.

- Repaired area attracts and holds rubber better than before the repair.

- Racing can resume within three days from restoration.

TVC Recommends P.TEN Marketing for Racetrack Marketing Management

Lead by founder and 20+ year industry veteran Ainsley Jacobs, P.TEN Marketing specializes in motorsports marketing, PR, creative, website, and support services for the automotive community.

By mixing a passion for motorsports with traditional marketing expertise, P.TEN’s team assists manufacturers, race teams, sanctioning bodies, and facilities to streamline their marketing and branding efforts.

P.TEN offers a comprehensive marketing services package specifically designed for racetracks and drag strip facilities. Click here to contact P.TEN!

P.TEN’s Team Assists Racetracks with Services Including:

- Building mobile-friendly websites with interactive event calendars, online ticketing, and more

- Managing the track’s social media page(s) such as Facebook and Instagram

- Keeping the online event schedule current with all additions and/or changes on the track website

- Posting race results, series points, and more to the track website

- Maintaining the track website with monthly backups and software updates

- Answering incoming messages and questions from people via social media

- Promoting upcoming races and events as well as track sponsors

- Writing and sending bi-monthly promotional email blasts with event information, schedule updates, news, etc.

- Creating a standardized graphic template to brand the facility’s own events and announcements

- Designing flyers for upcoming races and events

- Writing press releases about relevant track-related news, if needed

- Providing professional printing services for flyers, posters, banners, business cards, etc.

- Coordinating logistics for creation of trophies, champion jackets, winner’s checks, promotional items, etc. as needed

- Negotiating advertising placements and rates with local media outlets

- Management of track’s text message event alert system (if in use) for cancellations, etc.

- Providing basic IT support for web hosting, email accounts, and more